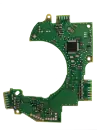

SMT (Surface Mount Technology) plays a key role in the creation of most of the devices that power our world, and we at Hronovský s.r.o. are extremely proud to be one of the European leaders in this type of manufacturing. We use the most advanced techniques and equipment to ensure the highest quality and efficiency in every step of our manufacturing process with IATF 16949 and VDA 6 standards, which are the applicable quality access control system in the automotive industry.

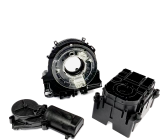

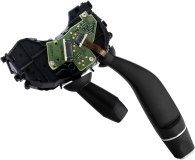

With years of experience and expertise, our team of dedicated professionals carefully organise every stage of SMT production to turn even your most creative concepts into reality. Our state-of-the-art equipment not only handles even complex designs with ease, but also ensures noticeably shorter lead times without compromising on quality. Whether you want to produce complex printed circuit boards for consumer electronics or robust components for industrial applications, our adaptable production processes are at your service.

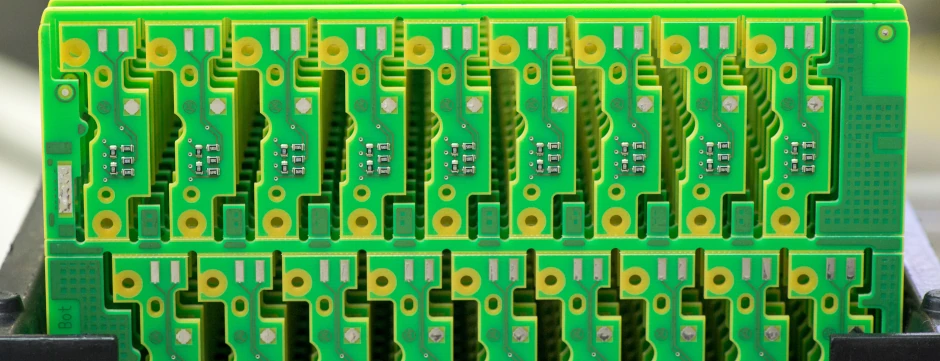

We currently use or perform: laser, SPI, SMT, AOI, ICT/FCT, milling, wave soldering and final inspection processes. In addition, 3 SMT lines with Juki super-fast modular milling machines and Depanelling DIVISIO 500 series - an intelligent system that interprets the status itself and also controls maintenance and optimization processes as needed. This allows us to produce up to 150,000 more parts per year.